Ah. Now you know why I started with a “Huh?”

Err yes and no.

So w the SFP/SPF+ interconnects you can use copper. While it is cheaper, usually, there are some other benefits like less heat. (Your transceivers … those bits at the end of the cable that plug in to the port… they can get hot… very hot depending on the transceiver and speed.) And at these interconnect speeds your copper interconnects are going to be limited by length. The longer the run, the lower the bandwidth.

CAT 8 will give you 40Gb/S speeds but at a limited length.

Also, there’s the issue of longevity. The fiber optic transceivers can go bad over time. Copper wires… less of an issue.

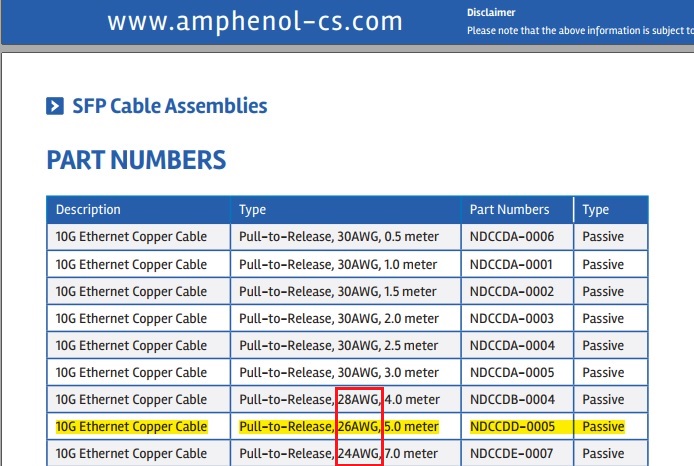

Now when you talk about the cable’s wire gauge… again not sure if you’re talking about the overall outer diameter or the actual wires inside. Since you’re talking about interconnects… if you are looking at a component from the bottom rack to a ToR on the top rack… its at most 6’ for a 42U rack. This is why you will sometimes see the ToR in the middle of the rack. (Oh wait… not sure if you actually know or have wired racks of servers.) But I digress. The point is that at these short distances you really don’t need to worry about the gauge of the individual wires. While I said 6’ max, most interconnects are 1m or less.

[edit] Those are patch cables 1m or less. Wiring in a cabinet is a bit longer. The point here is at these distances the wire gauge is less of an issue. (to a point) Its not like speaker wires where you have long runs.

Now w.r.t SFP/SFP+ the reason you don’t see a lot of copper, it is that you end up becoming bandwidth constrained. Fiber transceivers can do 400Gb/S speeds. Copper tops out at 40Gb/S which is your CAT 8 spec. Here the Hifi Rose is what? 1Gb/s port speed or 10Gb/s port speed depending on which product and port?

And yes… you can find different thicknesses of a jacket around the fiber. (Note if you reread what I wrote I said the fibers are the same size.) This is done to protect the fiber.